Mahan TMT 550D

We deliver right product, right measurement, right weight and right cost to our valuable customers.

Mahan TMT bar is manufactured by Magadh industries. This is first thermo mechanical technology in Bihar. This is used in Mahan TMT Bar. For this, we are using temcor technology. This is only used by Tata and sale in India. We have a team of expert engineers and technocrat. They are working day night for best quality TMT BAR.

Mahan industries unit is located in Patna at Didarganj area in the Mahan industries , we are focusing on quality control, less electricity, best in quality.

Mahan TMT is first choice of customers trust. Mahan industries distribute their products to selected dealers in last 10 years in market. We deliver right product, right measurement, right weight and right cost to our valuable customers. This is the sign of customers trust for us.

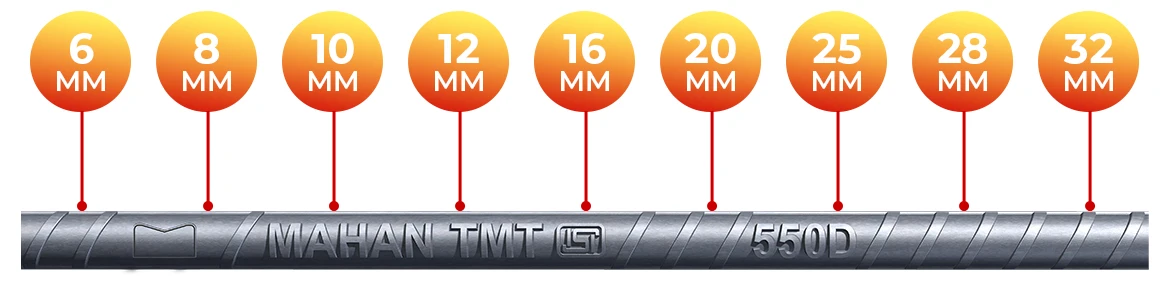

Product available in market 550D

MAHAN TMT 550D BARS

MAHAN TMT 550D BARS| Chemistry | Unit | IS:1786 Fe 415 | MAHAN TMT |

| Carbon | % | 0.33**max | 0.17-0.24 |

| Carbon ( c+mn/6 ) | % | – | 0.38max |

| Sulphur | % | 0.060max | 0.050max |

| Phosphorus | % | 0.060max | 0.045max |

| S & P | % | 0.110max | 0.090max |

| Nitrogen | ppm | – | 120max |

TMT bars find their application in many avenues. They are used for constructing:

Apart from the above, there are several other verticals where these bars are used.

Toll Free No: +91-9334300845

info@magadhtmt.com

M/S. मगध इंडस्ट्रीज प्राइवेट लिमिटेड, (CIN: U27100BR1998PTC008621), के द्वारा मगध TMT & महान TMT के नाम से अपना छड़ (स्टील सरिया) उत्पादन किया जाता है तथा हमारे मगध लिंक के माध्यम से मगध कलर कोटेड GC शीट एवं वायर रिंग भी बनाया जाता है, इन सभी मगध TMT ब्रांड उत्पादों को हमारे अधिकृत डीलर्स के माध्यम से संपूर्ण बिहार में बिक्री किया जाता है I संपूर्ण बिहार में हमारे कम्पनी के अधिकृत डीलर्स हैं जो कि उचित दर पर हमारे उत्पाद आपको उपलब्ध करतें हैं I आपसे आग्रह है कि मगध TMT के किसी भी उत्पाद को खरीदने के लिए अपने नजदीक के हमारे अधिकृत डीलर्स से संपर्क करें

चूकि मगध TMT पिछले कई दशकों से अपनी ब्रांड, गुणवत्ता एवं शाख के चलते ग्राहकों की पहली पसंद रहा है एवं बेहतर मजबूती के लिए सभी लोग चाहते हैं कि उनके मकान के निर्माण में मगध TMT सरिया ही इस्तेमाल किया जाए, इसलिए हमारी कंपनी से संपर्क करना चाहते हैं I हमारे ग्राहक बंधू आज -कल के चलन के अनुसार गूगल के माध्यम से मगध TMT कम्पनी का मोबाइल नंबर निकलने की कोशिश करते हैं और इस प्रक्रिया से उनको सही मोबाइल नंबर कि जगह किसी फर्जी गिरोह का मोबाइल नंबर निकल जाता है और यह फर्जी गिरोह अभी काफी ज्यादा सक्रिय हैं जो कि आपको फसाने की भरपूर कोशिश कर रहा I

ग्राहक जागरूकता के क्रम में आपको अवगत करना है कि ये जानकारी में आया है कि कुछ असामाजिक तत्व साइबर फ्रॉड के तहत फेक/गलत कोटेशन / बिल मगध TMT सरिया वास्तविक मूल्य से सस्ते दर पर कम्पनी से डायरेक्ट सप्लाई करने के नाम पर ठगी करने का प्रयास कर रहे हैं I इस तरह के ठगी के लिए फेक कोटेशन / प्रोफार्मा बिल में ग्राहकों को जो एडवांस फंड ट्रांसफर के बैंक खाता दिया जा रहा वो वास्तव में हमारे मगध इंडस्ट्रीज प्राइवेट लिमिटेड का बैंक खाता है ही नहीं I जिस बैंक खाता को वे कम्पनी का बैंक खाता बता रहे एवं आपको अग्रिम भुगतान के लिए आग्रह कर रहें, वास्तव में वो हमारे कम्पनी के नाम से नहीं रहता बल्कि किसी सन्दिग्ध ब्यक्ति के नाम पर रहता है जो कि इस लोगों के द्वारा इस तरह के फर्जीवाड़े के लिए ही उपयोग में लाया जा रहा है I इसलिए आपको अवगत करना है कि कृप्या इस तरह के किसी भी ऑनलाइन खरीद से बचने की जरूरत है नहीं तो आपके साथ साइबर ठगी हो सकती है

हमारी कम्पनी अपने स्तर पर भी इन जालसाजों के विरुद्ध क़ानूनी कार्रवाई कर रही है ताकि हमारे कम्पनी में बहुमूल्य ग्राहक बंधू को किसी तरह की कोई परेशानी न उठानी पड़े I

दुर्भाग्यवश इस तरह से पैसे की ठगी हो जाने के बाद पैसा वापसी के लिए आपको स्वयं से सरकार के राष्ट्रीय साइबर अपराध रिपोर्टिंग पोर्टल कम्प्लेन रजिस्टर https://cybercrime.gov.in करना होगा या टोल फ्री नंबर 1930 पर कॉल करके रिपोर्ट कर आगे की कार्रवाई जैसे F.I.R इत्यादि करनी होगी तथा पैसा वापसी के लिए हमारी कम्पनीज M/S मगध इंडस्ट्रीज प्राइवेट लिमिटेड , M/S मगध आयरन प्राइवेट लिमिटेड तथा M/S मगध लिंक किसी तरह से उत्तरदायी नहीं होगी I हमारे आधिकारिक संपर्क सूत्र जो नीचे दिए जा रहें हैं पर संबंधित सही बैंक खाते के सत्यापन के बाद ही पैसा ट्रांसफर करें I धन्यवाद !!

हमारे आधिकारिक संपर्क:

किसी भी साइबर अपराध की शिकायत राष्ट्रीय साइबर अपराध रिपोर्टिंग पोर्टल पर करें या 1930 टोल-फ्री नंबर पर कॉल करें।