Manufacturing Process of Magadh TMT

Billets – Strong Foundation of TMT Bars

The foundation of every Magadh TMT bar lies in its billets. Produced through advanced casting technology, billets are solid steel blocks made from refined molten metal. At Magadh, billets are engineered for uniform shape, size, and chemical composition, ensuring strength and durability from the very beginning. This solid base guarantees that the reinforcement bars manufactured later are free from internal defects, making them reliable for building homes, bridges, high-rise apartments, and infrastructure projects across Bihar and Jharkhand.

Lab Testing – Ensuring Purity & Strength

Before billets move forward, they undergo thorough laboratory testing. At this stage, the chemical composition, tensile strength, and carbon levels are checked to meet IS 1786 and global standards. Spectro analysis, bend tests, and elongation checks are performed to ensure uniformity and consistency. This guarantees that the raw material used in Magadh TMT bars has the purity, strength, and ductility needed for modern-day construction projects in Patna, Nalanda, Gaya, Nawada, Bhojpur, and other developing regions.

Reheating – Preparing for Rolling

Once tested, billets are placed into fully automated reheating furnaces. These furnaces maintain controlled high temperatures that soften the billets, preparing them for the rolling process without compromising their strength. Reheating ensures the billets achieve the right flexibility, which is crucial for forming accurate shapes and sizes in the subsequent rolling stages. This step allows Magadh TMT bars to maintain their superior tensile strength while staying bendable for practical use at construction sites.

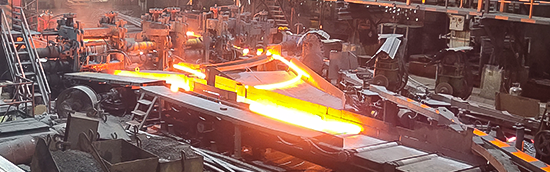

Roughing Mill – Shaping the Bars

Reheated billets are passed through the roughing mill, where they are rolled into elongated forms. This reduces the size of the billets while aligning their internal grain structure, improving overall strength and durability. At this stage, the billets begin transforming into the recognizable form of TMT bars. The roughing process is a vital step in creating the balance of toughness and ductility that Magadh TMT bars are known for.

Finishing Mill – Perfect Dimensions

After rough shaping, the semi-finished bars are sent through the finishing mill. This process ensures that the bars have accurate dimensions, consistent diameters, and precise rib patterns for excellent bonding with concrete. A smooth surface finish is achieved, eliminating imperfections. The finishing mill is where the reinforcement bars reach their final structural form, ready to deliver uncompromising performance in homes, offices, roads, and industrial buildings across Bihar.

Tempcore – Strength with Flexibility

Immediately after finishing, Magadh TMT bars undergo the Tempcore process, a specialized thermo-mechanical treatment. High-pressure water jets rapidly cool the outer surface of the hot bars, creating a hardened exterior, while the inner core remains soft and flexible. This combination gives Magadh TMT bars exceptional tensile strength, superior bendability, and earthquake resistance. The Tempcore process ensures that every Magadh TMT bar can withstand extreme stress while maintaining long-term durability.

Cooling Bed – Balanced Strength

Once treated, the bars are transferred to a long cooling bed where they undergo gradual air cooling. This slow cooling process is essential for balancing internal stresses and ensuring uniform mechanical properties throughout the bar. The cooling bed stage adds stability, ensuring the final product is tough enough for heavy-load structures while being flexible enough for safe construction practices.

Quality Control – Tested for Excellence

Magadh TMT bars are never dispatched without passing rigorous quality control checks. Each batch undergoes tensile strength tests, bend and re-bend tests, elongation assessments, and chemical analysis. Non-destructive testing methods are used to ensure that the bars are free from hidden flaws. This strict quality control guarantees that every bar leaving the plant is safe, strong, and compliant with national and international construction standards.

Storage & Dispatch – Ready for Delivery

After passing all tests, the bars are bundled, labeled, and stored in dry, moisture-free warehouses. Proper storage ensures that the bars remain corrosion-free until they reach customers. From the factory to the distribution network, each bar is handled carefully to preserve its quality. With a strong supply chain, Magadh ensures timely dispatch and delivery to builders, contractors, and engineers across Bihar and Jharkhand, supporting construction projects in Patna, Nalanda, Gaya, Nawada, Bhojpur, and other key regions.